Bruker의 'Lab Report XRF 171, S2 PUMA Series 2'에 관한 응용자료의 주요 내용은 다음과 같다.

Introduction

Ferrosilicon(FeSi) is an alloy containing two major elements, of silicon(Si) and iron(Fe). In steel production and casting it can serve several purposes: deoxidizing, preventing loss of carbon(C), removing harmful impurities(e.g., S, N), and even modifying the solidification process. To achieve the desired effect, certain purity standards need to be met.

The purity or quality of Ferrosilicon is determined by the concentration level of contaminants, such as aluminum(Al), phosphorous(P), sulfur(S), calcium(Ca), titanium(Ti), zirconium(Zr), and lead(Pb).

Energy-dispersive X-ray fluorescence(EDXRF) analysis is an easy and quick technology to accurately monitor and verify the Ferrosilicon composition, helping to ensure cost-efficient steel production.

Instrumentation

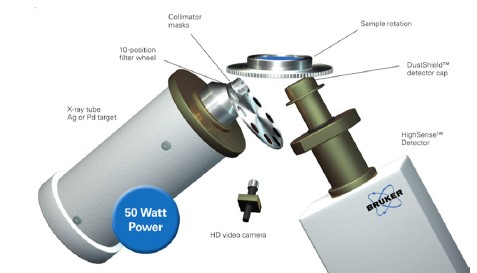

The S2 PUMA Series 2 EDXRF spectrometer is the optimal solution for your Ferrosilicon analysis. The combination of a 50 Watt X-ray tube with closely-coupled beam optics and the new HighSense™ detector technology enables optimal sample excitation, resulting in outstanding analytical performance(Figure 1).

In contrast to other methods like AAS(Atomic Absorption Spectrometry) and ICP-OES(Inductively Coupled Plasma Optical Emission Spectrometry), a simple one-time calibration makes the S2 PUMA ready for your application. This calibration is then checked daily by running a control sample. Once the system is calibrated, the TouchControl™ user interface makes it really easy to run routine samples after minimal introduction.

Sample Preparation

Ten grams of the calibration standards and the unknown samples were weighed out and pulverized using a tungsten-carbide(WC) ring and puck mill for 3min. The samples were then pressed at 30 tons for 30s using a 40mm die and 1.0g of wax binder. The result are robust and homogeneous pellets(Figure 2) that can be measured in vacuum mode for the best detection of lighter elements(Al and Si) combined with the lowest cost of operation(no Helium!). The preparation is simple and reproducible.

It can be performed with any grinder and pellet press.

Figure 1: HighSense™ beam path of the S2 PUMA Series 2

Figure 2: Example for finished pressed pellets

Table 1: Measurement Parameters

Calibration Details

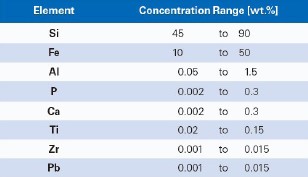

A combination of certified reference materials(CRMs) standards and validated secondary standards(10 in total) were used for building a dedicated Ferrosilicon calibration for eight elements, covering a wide range of concentrations(Table 2).

The calibration was performed with Bruker's intuitive spectrometer software, SPECTRA.ELEMENTS. This integrated XRF spectroscopy package guides the operator smoothly through the calibration process and offers a wide range of matrix and interference corrections(theoretical, empirical, fundamental parameters) to achieve optimal performance.

Table 2: Calibration range of the FeSi standards

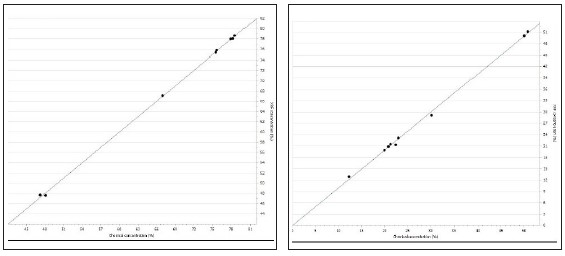

Figure 3: Example calibration curve: Si Figure 4: Example calibration curve: Fe

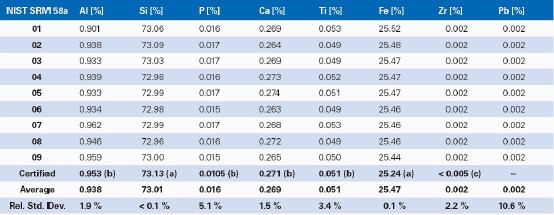

Table 3: Precision test. (a)Certified value, (b)Reference value, (c)Informative values

SampleCare™

Bruker’s unique SampleCare technology(Figure 5) protects the vital system components in the event of sample breakage or liquid cup leakage. The sample detection system prevents the measurement of liquid or powder samples under vacuum. SampleCare is key for high system uptime and short & easy maintenance.

Figure 5: SampleCare™:

1. Grabber with automatic sample detection

2. DustShield™ detector cap

3. Dust reservoir

4. Filter wheel

Conclusion

This lab report highlights the outstanding capabilities of the S2 PUMA Series 2 for quality control of Ferrosilicon and similar material. Equipped with modern software solutions and state-of-the-art hardware, the S2 PUMA is ideally configured to enable best-in-its-class analytical performance.

The S2 PUMA EDXRF spectrometer is ready for challenging industrial environments and applications with its TouchControl interface and its SampleCare technology. The 22-position XY Autochanger(Figure 6) enables high sample throughput while keeping all fexibility. Mixed batches can be loaded(liquid, powder, solid, ...) and samples can be added at any time. You need to change priorities and quickly analyze a production sample? No problem with the S2 PUMA XY Autochanger.

Figure 6: XY Autochanger with 20-position EasyLoad tray and 2 extra fixed positions

Bruker의 'S2 PUMA'에 대한 상세한 내용은 Reference(참고자료)를 통하여 확인할 수 있다.

Reference(참고자료): Bruker application note, 3 pages

Model Name(모델명): S2 PUMA

The Person in Charge(담당자): Ji Gisu

Maker(제조사): Bruker

Country of Origin(원산지): Germany

Mail inquiry: gisu.ji@dksh.com

Data Services(자료제공): DKSH Korea

<이 기사는 사이언스21 매거진 2022년 10월호에 게재 되었습니다.>