Bruker의 'Bruker S2 PUMA Series 2 Lap Report'에 관한 응용자료의 주요 내용은 다음과 같다.

Analysis of Elements under RoHS II/WEEE/ELV in accordance with ASTM F2617-15 with the S2 PUMA Series 2.

Introduction

The EU directives 2002/95/EG and 2011/65/EU, commonly known as “RoHS” "RoHS II"(Restrictions of Hazardous Substances), regulate the use of hazardous materials in components used in electronic devices. The purpose of these directives is to ban problematic substances from electronic scrap, such as leaded solder(see Figure 1), Cd in batteries(see Figure 2), and Cr in protective coatings. The main substances targeted are lead, mercury, cadmium, bromine, and chromium among some organic compounds.

Other jurisdictions, such as China, Japan, the US and Korea have their own, but similar directives. Further regulations focus on e.g. heavy metal content in used cars(ELV, for “End of Life Vehicles”) and recycling of electronic equipment(WEEE, for “Waste of Electrical and Electronic Equipment”).

The implementation of all of these directives requires adequate analytics. The S2 PUMA Series 2 is the right instrument when it comes to compliance with RoHS and related applications according to the norm ASTM F2617-15.

Figure 1: Soldering on microcircuit.

Figure 2: Batteries often contain heavy metals.

Fast and Reliable When It Counts: S2 PUMA Series 2

The S2 PUMA Series 2 is the high-performing benchtop energydispersive X-ray fluorescence(EDXRF) spectrometer and

the most versatile EDXRF instrument. It is available as Single, XY Autochanger for high sample throughput(see Figure 3), and as Carousel option which can accommodate almost any sample in its sample chamber(see Figure 4). For this lab report we used the S2 PUMA Series 2 XY Autochanger with an X-ray tube with Pd target and the XFlash® silicon drift detector(SDD). The S2 PUMA Series 2 XY Autochanger offers unique sample handling among benchtop EDXRF instruments: Larger sample series can be measured in one session while samples can be exchanged during the analysis.

The ergonomic TouchControl™ interface for independent routine operation without any PC peripherals and the powerful instrument software suite SPECTRA.ELEMENTS guarantee the highest analytical flexibility.

Figure 3: The S2 PUMA Series 2 XY Autochanger guarantees high sample throughput.

Figure 4: The S2 PUMA Series 2 Carousel’s sample chamber can hold microcircuits in one piece.

Measurement Conditions and Set-Up

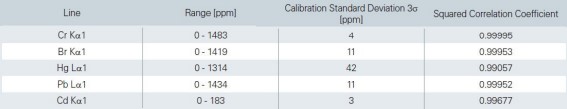

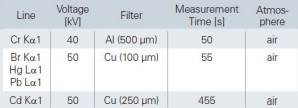

For this lab report a calibration with nine reference polymer samples was set to measure the five elements Cr, Br, Cd, Hg, and Pb. The samples were hot-pressed to a thickness of 2mm. Table 1 shows the concentration ranges of the different reference samples and the achieved standard deviations(SD) and squared correlation coefficients(R2). Measurements were conducted under air twith three measurement regions. The tube current was optimized and fixed on order to gain maximum count rate for the various elements. Table 2 lists details on the measurement ranges for the respective ranges.

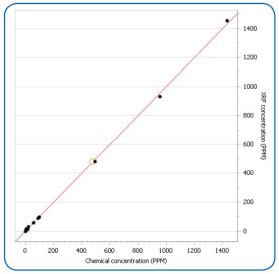

The excellent calibration curve for Pb Lα1 with an R2 of 0.99952 and a standard deviation of 11 ppm is given in Figure 5.

Analytical Precision

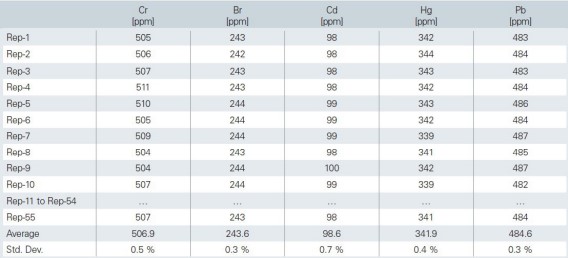

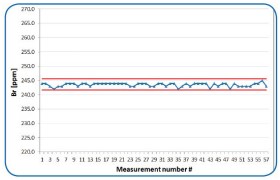

A polymer QC sample was used to run a repeatability test. The same sample was measured 55 times every hour over four

consecutive days. For each measurement the sample was loaded into and un-loaded from the measurement chamber. These

measurements show the very high precision and stability of the instrument. Table 3 shows an excerpt of the analysis results. The standard deviation values here show the excellent repeatability that is achieved on the S2 PUMA Series 2.

Figure 6 shows the results of the repeatability test for Br graphically. The red lines show the three standard deviations confidence interval of the measurements. Values such as those can also be defined in SPECTRA.ELEMENTS for immediate feedback if any samples run out of their specification during process control.

Table 1: Calibration details for RoHS sample measurements with concentration ranges of the elements in the reference samples, their SD, and R2.

Table 2: Measurement conditions for the respective ranges.

Table 3: Excerpt of results of the repeatability test on polymer QC sample.

Figure 5: The calibration curve for Pb Lα1 with an excellent standard deviation of 11 ppm.

Figure 6: Repeatability results for Br with red lines indicating three SD.

Summary

The combination of high-power X-ray tube and the HighSense™ beam path delivers excellent analytical performance. The closely coupled beam path ensures best sensitivities. Measurement under air means lowest cost of ownership as no expensive helium as purging gas is required.

The straightforward sample preparation is simple and does not require any chemical digestion as might be required for other analytical techniques.

Industry-leading features such as the XY Autochanger sample handling with the unique optional integration into automated

environments and TouchControl make product quality control quick and reliable. This makes the S2 PUMA Series 2 the ideal partner for RoHS, WEEE, ELV, and related applications.

Bruker의 'Bruker S2 PUMA Series 2 Lap Report'에 관한 궁금한 내용은 본 원고자료를 제공한 DKSH 코리아(주)를 통하여 확인할 수 있다.

Reference(참고문헌): Bruker application note

Model Name(모델명): S2 PUMA Series 2

The Person in Charge(담당자): Hong Jihye

Maker(제조사): Bruker

Country of Origin(원산지): Germany

Mail inquiry: dksh.info.tec@dksh.com

Data Services(자료제공): DKSH Korea

<이 기사는 사이언스21 매거진 2022년 1월호에 게재 되었습니다.>