INTRODUCTION

Liquid drug formulation involves pipetting buffering agents, tonicity modifiers, viscosity, enhancers and reducers. Most of these liquids are viscous and interact directly with pipettes when transferring microliters of solution.

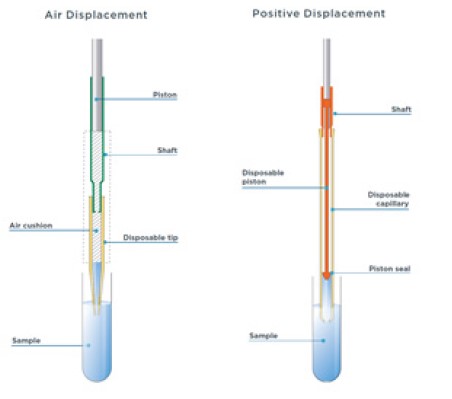

Dispensing systems in the laboratory can either employ an air displacement system, as in a standard pipette, or use a positive displacement system. In an air displacement pipette, an air cushion separates the liquid in the plastic tip from the piston inside the pipette.

Like any gas, the air cushion between the piston and liquids interacts according to the characteristics of liquids(density, viscosity, volatility, presence of surfactants) as well as partly by lab or protocol condition, (uploaderature variation, humidity).

A liquid with a high viscosity flows slowly into and out of the tip, creating the possibility of residual carryover when dispensing.

Additionally, if the tip is withdrawn too soon from the liquid reservoir, an air bubble forms in the tip, reducing the liquid volume and decreasing accuracy.

Conversely with positive displacement pipettes, the liquid does not come into contact with the pipette itself.

Samples are instead aspirated and expelled through a capillary via a piston. There is no air cushion, in this way, the physical properties of the liquid have very little influence on the volume being aspirated or dispensed.

This application note demonstrates the advantages of using positive displacement pipettes, like the Gilson MICROMAN® E, over air displacement pipettes in pharmaceutical formulations requiring accurate and precise pipetting of viscous liquids.

Materials & Methods

The results compare the impact of a solution’s viscosity and the type of pipetting mode(forward and reverse) of an air displacement pipette, with that of a positive displacement pipette, Gilson MICROMAN® E, on the accuracy and precision of volume dispensed by gravimetric measurements.

Solutions of 100% glycerol(1.26g/mL) served as sample material, showing the impact of viscosity while pipetting pharmaceutical solutions. Glycerol is also used in many pharmaceutical products as an excipient and formulation aid, and can provide emollient and other performance benefits to a formulation.

For each test, 10 samples of distilled water grade 3(ISO 3696) and glycerol with a nominal volume of 100μL were dispensed with an air displacement pipette with D200 tips. The tests were then repeated using a Gilson MICROMAN E positive displacement pipette model M100E with CP100 capillary pistons.

Two pipetting modes are used: forward mode and reverse mode. Reverse mode is only used with the air displacement pipette.

The systematic error (inaccuracy) and random error (imprecision) of each pipette were determined according ISO 8655 standards.

Principle and Pipetting Mode Description:

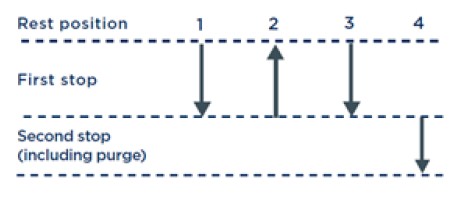

The forward mode is the standard pipette aspirate and dispense mode (Figures 1 and 2). In general, the precision of the forward mode relies on precise draining by air pressure(air displacement pipette) or internal wiping of the pipette barrel(positive displacement pipette).

Figure 1. Two Pipetting Concepts-Air and Positive Displacement

Figure 2. Forward Mode Pipetting

1. Preparation: Hold the instrument in a nearly vertical position. Depress the plunger smoothly to the first stop position.

2. Aspiration: Immerse the pipette tip in the liquid. Allow the plunger to move up smoothly to the rest position. Wait one second so that all the liquid has time to move up into the tip.

3. Distribution: Place the pipette tip at an angle (10° to 45°) against the inside wall of the receiving vessel. Depress the plunger smoothly to the first stop position.

4. Purge: Wait one second, and then depress the plunger to the second stop position. This “blow-out” stroke expels any remaining sample from the tip. Remove the pipette tip end from the sidewall by sliding it up the wall.

Forward mode with a positive displacement pipette is similar to the forward mode of an air displacement pipette, but the purge step is replaced by the ejection of the capillary pistons.

1. Preparation: Press the plunger button to the first stop. The piston moves to the appropriate position.

2. Aspiration: Immerse the capillary piston in the liquid. Release the plunger letting it move up to the home position. The piston moves up and the ambient pressure forces the desired volume of liquid through the orifice into the capillary.

3. Distribution: Press the plunger button to the first stop. The piston moves down and expels the liquid out of the capillary.

4. Ejection: Press the plunger all the way down to the second and last stop. Capillary and piston are ejected without hand contact.

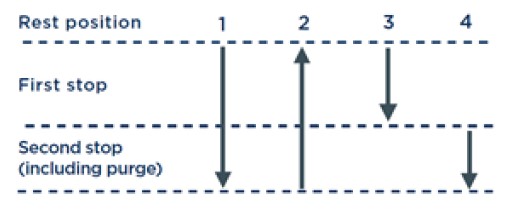

Reverse mode pipetting is used for pipetting solutions with a high viscosity or a tendency to foam. The purge stroke is used during preparation. During aspiration, an amount of liquid equal to the amount of purged air is added. This amount compensates for the liquid that remains as film inside the tip during dispensing.

Figure 3. Reverse Mode Pipetting

1. Preparation: Hold the instrument in a nearly vertical position. Depress the plunger smoothly to the second stop position.

2. Aspiration: Immerse the pipette tip in the liquid. Allow the plunger to move up smoothly to the rest position. Wait one second so that all the liquid has time to move up into the tip.

3. Distribution: Place the pipette tip at an angle(10° to 45°) against the inside wall of the receiving vessel. Depress the plunger smoothly to the first stop position. Wait one second.

4. Re-aspiration: If the pipette tip is to be reused for the same sample, maintain the plunger in the intermediate position for subsequent immersion for the next pipetting cycle and restart step 2(aspiration).

5. Complete purge: Wait one second and purge. If the pipette tip will not be re-used, depress the plunger to purge position over an appropriate waste container and then eject the tip.

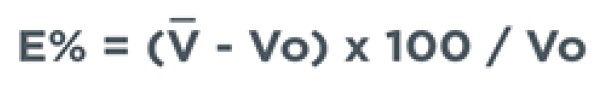

Calculation Description

The average volume was determined by gravimetric measurements. The systematic error or inaccuracy of a pipette can be expressed as a percentage of the nominal volume:

E : systematic error

Vo: nominal volume

V̄: mean volume

A percentage of random error or precision was calculated using this equation:

RSD : random error or relative standard deviation

SD : Standard deviation

Vi : individually measured volume

n : number of measurements

V̄: mean volume

Results and Discussion

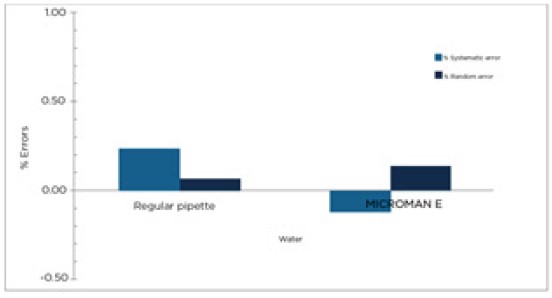

During pipette calibration, as shown in Figure 4, the systematic and random errors for pipetting 100μL of water are similar for the standard pipette(0.23% and 0.06% respectively) to that of the MICROMAN® E (-0.12% and 0.14%).

Figure 4. Systematic and random errors of water pipetting with MICROMAN® E versus air displacement pipette. Measurements were based on the average of ten gravimetric measurements per sample.

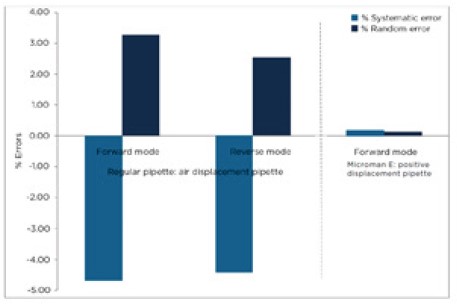

However, with glycerol, as shown in Figure 5, the systematic and random errors vary considerably with the standard pipette(-4.67% and 3.25% respectively), whereas with MICROMAN® E(0.16% and 0.12%) they stay similar to the specifications with water.

Besides, with the standard pipette, the systematic and random errors of the standard pipette in forward mode(-4.67% and 3.25% respectively) are similar to those of the reverse mode(-4.38% and 2.54%). These results are higher than those of the MICROMAN® E in forward mode(0.16% and 0.12%).

Figure 5. Comparison of systematic and random errors of viscous liquid pipetting with standard pipettes versus MICROMAN® E in forward and reverse mode. Measurements were based on the average of ten gravimetric measurements per sample.

When accurate and precise dispensing of viscous solutions is critical, a standard pipette is of limited use, regardless of the pipetting mode. With viscous liquids, the systematic or random errors fall outside the error limits defined for water, and the individual measurements vary considerably. In contrast, the results obtained with MICROMAN® E are similar between glycerol and water.

CONCLUSIONS

MICROMAN® E, a positive displacement pipette with capillary pistons efficiently pipettes the types of viscous liquids commonly used in pharmaceutical formulations. Viscous liquids are fully and quickly dispensed without leaving residual sample left in the tip. When pipetting viscous solutions, the different pipetting modes of an air displacement pipette are not recommended;

MICROMAN® E and with capillary pistons are the recommended solution to pipette with accuracy and precision.

Gilson의 'MICROMAN® E: Improve Pipetting of Viscous Liquids in Pharmaceutical Formulations'에 대한 궁금한 내용은 본 원고자료를 제공한 한국분석기기(주)를 통하여 확인할 수 있다.

Reference(참고문헌): 1.Gilson SAS, 2014, Nadège BELHADJ, Achieve Precise Pipetting of Problem Liquids with MICROMAN® E

2.Gilson SAS, 2015, Guide to Pipeting

Model Name(모델명): Microman® E

The Person in Charge(담당자): Hyesook An

Maker(제조사): Gilson.

Country of Origin(원산지): France

e-mail: kaisco1@kaisco.co.kr

Data Services(자료제공): Gilson.